To prepare ourself for the GIZ project “Transitioning to Low Carbon Sea Transport” we had the plan to build the prototype of a sustainable fishing and cargo vessel anyway before we would return to the RMI. Since it would be great to use the prototype even beyond its initial purpose we made the decision to build some sort of upgraded cargo proa. This is what we had on our wish-list when we were planning and designing Proasis in 2018/19:

Our Requirements on Proasis

Proasis, the boat we are going to build, will be a small low cost and low tech proa, made to cross oceans – time will show which oceans 😉

The philosophy behind Proasis is to keep everything as simple (and inexpensive) as possible. What we don’t really need for our mission we won’t get and don’t need to pay for (that counts for size as well!). What we don’t have doesn’t weight us down and helps to keep the design sleek and light. Sleek and light means we don’t need an engine, winches, furler or other marine hardware. No hardware means no maintenance work and further expenses.

Proasis doesn’t need to be huge. We will sail it single or double handed most of the time, for short distance maybe with up to 5 people. Accommodation and storage for long distances (food and water for 20 days) is only required for two.

The crew accommodation will be as basic as the entire design: we doesn’t need more than two cozy bunks, a nice and comfortable place to sit and work, a place for a stove and the navigation. All of that in one place, sheltered from weather. Steering devices and sheets always accessible without stepping outside.

A boat with a short handed crew needs to sail as easy as possible. It must be 100% operable when single handed, even under the harshest conditions.

What we are going to build

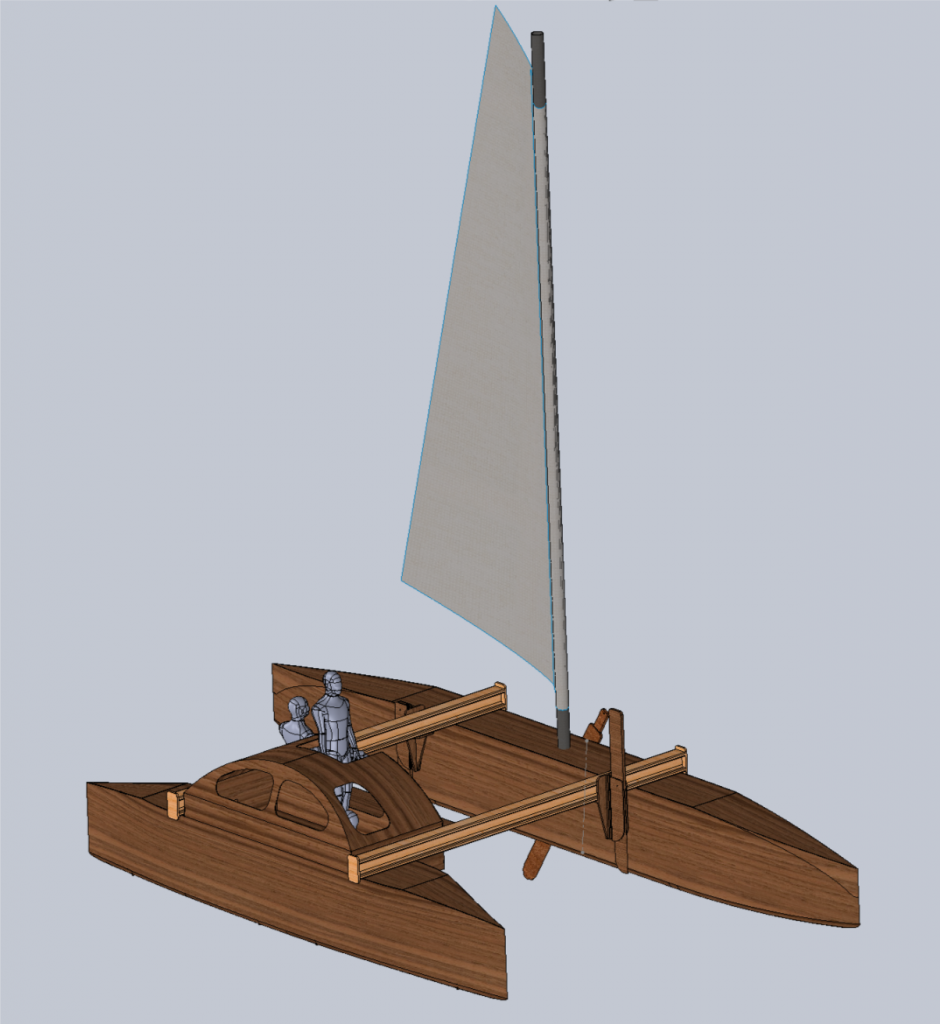

A proa is the least boat possible (material wise) and very quick to build. Our proa will be 9m long and 4m wide, made from industrial plywood and timber. Dimensions according to the standard size of ply sheets and simple box section shapes will cut down material cost and construction time.

Accommodation will be only in the smaller windward hull, storage for food, water and everything else in the bigger leeward hull. The reason why we push the accommodation into the windward hull and thus end up with a second hull, not only a floater, are the conditions we find in our backyard, the baltic sea. Its often cold and wet so we appreciate some shelter while sailing. It’s also a nice feature that it is possible to access the cabin even in strong rain without water getting in (the hatch is always open to the leeward side). Aside of that, from our point of view a cruising multihull should never lift th windward hull. To assure that we follow the example of the Fijian drua and opt for maximum righting moment by placing weight to windward.

A net between the hulls offers lots of extra space outside. On anchor, this open space could be easily converted into a huge living room by a deck tent.

Everything is clean and reduced to a minimum. Sailing and shunting will be effortless due to fewer and lighter components as on conventional yachts. Kick-up rudders and a swinging lee board make the boat safe when operating in shallow waters and allow to beach it uncomplicated.

The proa will be build almost without any metal. Especially screws and nails won’t be used, as they often fail in marine environment. Joints are made by strong glue (for permanent fix) or lashings (for temporal fastenings). The crossbeams are lashed to the hulls i. eg. to allow a controlled flexibility of the platform – important to reduce peak loads for an even lighter design.

Proasis is made from floating materials only. That makes her a real unsinkable craft! Even completely submerged or crushed into pieces she will keep her crew floating: very safe! We don’t belong to those crazy people who attache a block of heavy lead to their boats 😉